At this year's investors' meeting, Tesla announced the mass production of the new 21700 battery jointly developed by Tesla and Panasonic, and stressed that it was the battery with the highest energy density and the lowest cost among the mass-produced batteries. Samsung SDI also launched a new type of 21700 battery with the same specification. The global Lithium-Ion giants have turned to 21700 batteries one after another. Can the wind of model change blow

Cylinder battery reform approaching - large scale trend

1. 18650 meets the needs of the stage and takes on the historical mission of the primary application stage of power lithium battery

3At the beginning of the development of power lithium battery, Tesla's success in adopting 18650 greatly guided the application of 18650 battery in the field of electric vehicles. 18650 battery has highly mature technology and high degree of automation. As a standardized product, the yield and consistency are guaranteed (the good rate of foreign three star enterprises is more than 98%, and the domestic market is generally more than 90%), and the cost is low (2 ah unit price) At present, China's mainstream power lithium batteries are mainly 18650 cylinders, such as foster, bicker power, Zhihang new energy, delonair, Tianpeng power, Yiwei lithium energy and other companies adopt the cylinder 18650 product technology line. However, the 18650 is limited by the volume limit, which is generally between 2.2-3.6ah. Under the current requirements for the continuous improvement of power battery energy pack energy, the space for monomer capacity improvement is limited, and the promotion progress in the future will also slow down.

1.2. Model upgrade: "thickening and lengthening" is the trend

There are two ways to improve the energy density of power lithium battery: one is to improve the mechanism and performance of lithium battery material system, which requires high requirements for material development and matching, and the progress is slow. The second is the production control of model and process

The target of power lithium battery energy density will force product model transformation and promotion. The current subsidy standard for new energy vehicles before 2020 is positively related to the energy density of power lithium batteries. Therefore, in the case of no great breakthrough in the battery material system, it is an inevitable trend to appropriately increase the "diameter and length" of batteries to obtain higher effective capacity from the product model design. 18650 has initially completed the historical mission of the primary application stage of power lithium batteries In the future, "larger size" lithium battery models will emerge.

In the long term, according to the national guidelines on the energy density of power lithium batteries, China has clearly proposed that the energy density of power battery unit should exceed 300wh / kg in 2020, and the energy density of power battery system should reach 260wh / kg; the energy density of power battery system should reach 350wh / kg in 2025. Taking the 18650 battery of bicker company as an example, the energy density of ternary lithium battery is 215wh / kg, which needs to be increased by 39.5% to reach the target of single battery in 2020. In the general direction, state subsidies promote enterprises' endogenous power to improve battery energy density, and product model improvement is much faster than that of materials (NCA, 811). 21700 batteries that increase energy density by increasing volume will undoubtedly become the focus of enterprises. The continuous improvement of power lithium battery energy density is bound to continue to promote the change of Li ion battery model.

2 "thick and long" 21700 battery rolled 18650 in performance and cost

2.1. Battery energy density increased by more than 20%

The energy density of 21700 battery is better than 18650 battery. According to the information disclosed by Tesla, under the existing conditions, the energy density of its 21700 battery system is about 300wh / kg, which is about 20% higher than that of its original 18650 battery system (250wh / kg). At the same time, according to the test data of Panasonic's power lithium battery, the volume energy density of its 21700 battery is much higher than that of 18650 battery. The increase of energy density of single cell is much higher than that of group by 20%

2.2. The cost of battery system will be reduced by about 9%

The cost of 21700 decreased by about 9%. According to the battery price information disclosed by Tesla, it is estimated that the price of 21700 power lithium battery system is $170 / wh, which is about 8.1% lower than that of 18650, which is 185 US dollars / wh. The cost of 18650 system is about 171 US dollars / wh. After using 21700, the system cost can be reduced by about 9%, reaching 155 US dollars / wh.

With the increase of monomer capacity, the number of accessories required for pack decreases in the same proportion, which leads to the decrease of pack cost. After switching from 18650 model to 21700 model, the capacity of single battery can reach 3 ~ 4.8ah, which is greatly increased by 35%. The number of batteries required under the same energy can be reduced by about 1 / 3. Tesla models electric vehicles use 7104 18650 batteries in series and parallel to form a battery pack. It is expected that the number of battery cells in the new Model3 will be greatly reduced. While reducing the difficulty of system management, the number of metal structure parts and conductive connectors used in the battery pack will be reduced in the same proportion. Tesla's pack cost accounts for about 24% of the total system cost. It is estimated that the cost of battery pack will decrease significantly.

The contribution of lightweight. Samsung mentioned that after switching to the new 21700 battery, the system can reduce the components and weight by 10% compared with the current battery. As a result, the weight of the battery pack will be further reduced, and the energy density of the whole vehicle will be partially improved.

2.3. Why 21700?

21700 is not superior to other models in absolute performance, but the result of comprehensive balance of physical and economic properties. The increase of the physical size of the cylindrical cell not only improves the energy density, but also negatively affects the performance such as cycle life and rate. It is estimated that every 10% increase in capacity will reduce the cycle life by about 20%; the charge discharge rate will be reduced by 30 ~ 40%; at the same time, the temperature rise of the cell will be about 20%. If the size continues to increase, the security risk will be increased.

In terms of economy, the cylinder cell is improved in 18650 mature process, and the cost is controlled on the premise of ensuring the yield and consistency. If the size is too large, the safety and adaptability will be reduced, leading to the larger cylinder 26500, 32650 and other reasons can not occupy the mainstream market on a large scale.

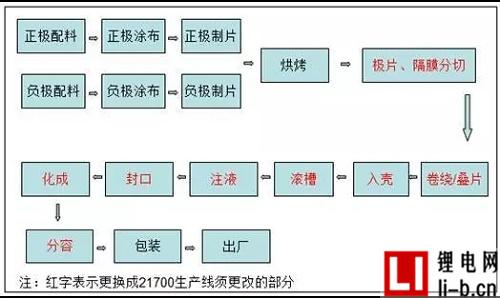

The general production change cost of production line is low. First of all, domestic lithium battery manufacturers are in the investment period of large-scale production line construction. It is estimated that the effective capacity in this year is expected to be about 60-70gwh. The construction of short-term lithium battery capacity supply side is basically completed. The growth rate of new investment in the future will slow down. The production of foster, bicker power, Zhihang new energy, delonair, Tianpeng power, Yiwei lithium energy has been greatly expanded in recent two years The production lines of all enterprises are mainly 18650. From the point of view of stock production line, 18650 cylinder is the main column. It is more convenient for battery manufacturers to transform from the original mainstream 18650 to 21700. It is easier to switch the production line equipment from general purpose to 21700, and it will not invest too much equipment technical transformation cost and new equipment investment. So we expect a considerable growth of 21700 batteries in the future. The transformation of production line mainly involves the cutting, winding, assembly and formation of the middle and rear sections, and the mold adjustment cost for the semi-automatic line is relatively low.

Figure 4: column manufacturers only need to adjust part of the production line to transform 21700 batteries

3. Beach landing - pioneers have accelerated 21700 layout

Some 18650 battery companies in China have approved Tesla 21700 route and are also making relevant layout. If the enterprise's own strength in improving material performance through R & D is not strong, the most direct way to enhance energy density is to make large-scale vehicles to enhance energy density through physical means. Bicker, foster, Mengshi, Tianpeng and other cylindrical battery enterprises have announced that they will put into production 21700 batteries in the future capacity expansion. Among them, Lin Jian, vice president of BIC battery research and development, said that the energy of BIC 18650 battery reached 3.5 ah after mass production. The next step is to develop 21700 battery. By combining high nickel and silicon carbon, the mass production energy of 21700 battery can reach 6.0ah. More quickly, Tianpeng, foster and other companies are available. The equipment configured in Tianpeng No.2 production base produces 21700 products, and the product energy density can reach 200-240wh / kg.

At the end of 2016, Shenzhen yongdeli new energy Co., Ltd. began to develop 21700 high rate lithium batteries, and began to put them into the market in June 2017, winning high praise from e-cigarette and other industries! Shenzhen yongdeli new energy Co., Ltd. focuses on the production and sales of large capacity and high rate lithium batteries. The main types of steel shell lithium batteries are: 18350 1100mah 15A; 18650 1800mAh 40A; 18650 2600mAH 35A; 18650 3100mah 35A; 20700 3200mah 40A; 21700 3750mah 40A; 26650 4300mah 40A; as well as soft package cylindrical cell and soft package square cell.

Yongdeli New Energy Co., Ltd.

Address: No.379 Changfeng Road, Gongming town, Guangming New District, Shenzhen, Guangdong Province, China

Tel: 86-755-2715 0168

Fax: 86-755-2715 0688

Website: www.xianbm.com

Copyright ? Yongdeli New Energy Co., Ltd. All right reserved 粤ICP备17056655号 Address: No.379 Changfeng Road, Gongming town, Guangming New District, Shenzhen, Guangdong Province, China